|

Iraqi BADR-2000 missile project

(and their one-stage version Badr-2000

Junior)

Norbert Brügge, Germany

Beginning in 1984/1985, Iraq started a cooperative

effort with Egypt and Argentina to develop a high-technology, two-stage missile

system designed for a range of around 1,000 km, called BADR-2000 in Iraq,

Vector in Egypt and

Condor-II in Argentina. This missile was to be built first as a two-stage.

Iraq declared that, in the beginning of 1989, it attempted to complete the

BADR-2000 project by itself, in particular the production of solid propellant

motors In fact, the only BADR-2000 missiles delivered to Iraq were two mock-ups

of the complete missile that were to be used for training. The BADR-2000 Junior

is a single-stage version, which was developed after the death of the BADR-2000.

Post the war Iraq continued to work on the SRBM system with ranges of less

than 150 km authorized by the United Nations.

Personnel previously involved with the BADR-2000 missile are working now on

the smaller Al-Fat'h missile. The Al-Fat'h uses probably the rocket motor

of Argentina's Condor-I (Alacran) as a replica.

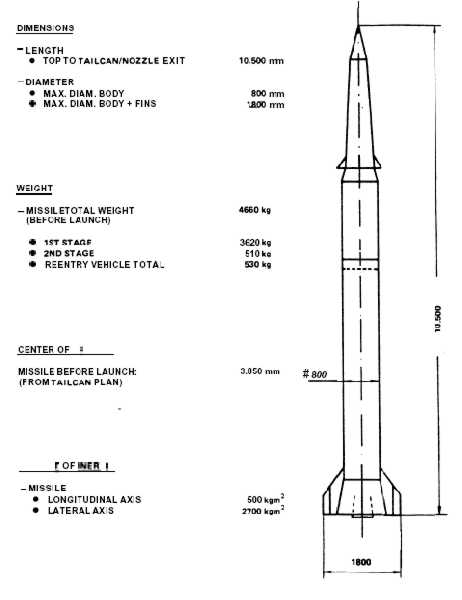

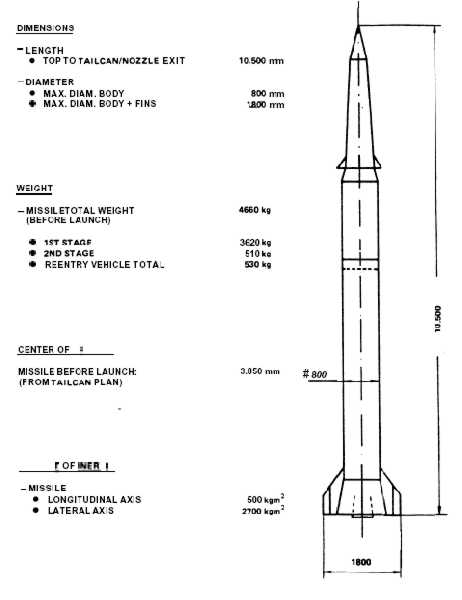

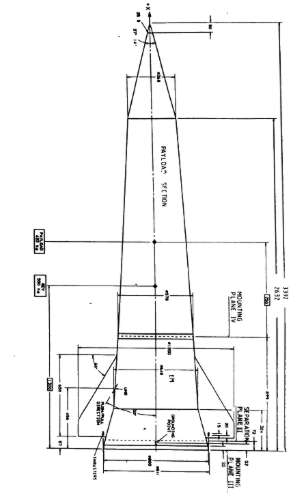

The BADR-2000, as described in the concept definition report, was to be a

mobile, twostage, medium-range, surface-to-surface, ballistic missile system

with a separating reentry vehicle as payload. The system included the missile

itself and all equipment concerned with transport and handling, firing position

survey, trajectory computation, launch preparation, missile launch, command

communication, checkout and power supplies as well as service and support

equipment.

Boost stage rocket motor

The first stage boost rocket was 800mm in diameter with a maraging steel case,

filled with cast composite HTPB propellant. At the time Iraq negotiated their

contract with the foreign country, the design for this motor had already been

established.

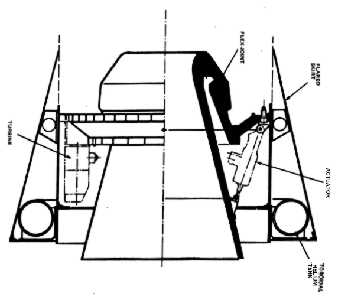

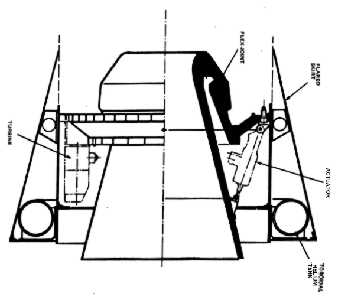

Thrust vectoring for missile control in pitch and yaw during the boost phase

was to be provided by a flexible-joint nozzle with hydraulically operated

actuators powered by pressurized stored helium gas. The flexible-joint nozzle

was an advanced design, using alternating rings of elastomeric material (natural

rubber) and steel reinforcements to allow articulation of the nozzle at the

throat region.

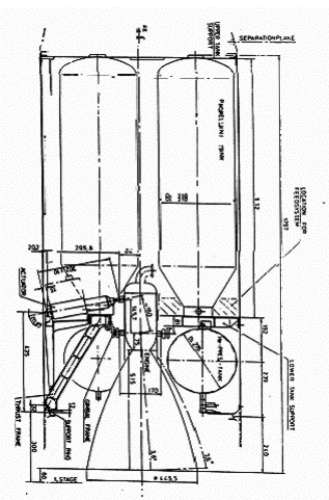

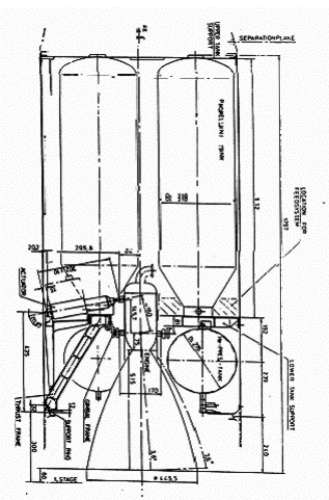

Second stage rocket engine

The second stage rocket engine, according to the contract, was to be based

on an existing, third-party liquid propellant engine (LPE) using MMH (monomethyl

hydrazine) as fuel and nitrogen tetroxide as oxidiser, each stored in two

separate pressurized tanks. At the end of the Concept Definition Phase, the

propellants were listed as UDMH (unsymmetrical dimethyl hydrazine) as fuel

and MON 7 (mixed oxides of nitrogen) as oxidizer. A gimbaled nozzle, actuated

by compact electro-mechanical units, would provide thrust vector control.

The maximum burn time for the engine was 40 seconds.

The engine is shut down by two valves that are pyrotechnically activated by

the guidance and control package when the missile has attained the required

velocity for the selected range. Although a second stage engine design was

apparently available to the missile design team at the time of signing the

contract, further development work was required and design modifications were

carried out in the concept definition phase. During the sustain phase, roll

control of the second stage vehicle is provided by the cold gas thruster system

housed in the re-entry vehicle.

It is clear that, from the outset of its negotiations with the foreign country,

Iraq wished not only to acquire a missile system of several hundred kilometers

range, but that it was also intent on acquiring the capacity and technology

to build composite solid propellant rockets in-country, starting with the

BADR-2000 first stage motor without flexible-joint nozzle. (BADR-2000 Junior).

|

|

|

|

BADR-2000 with flexible nozzle

|

|

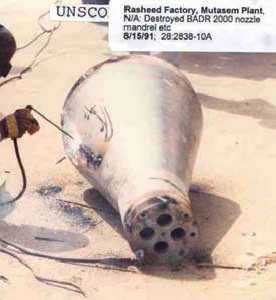

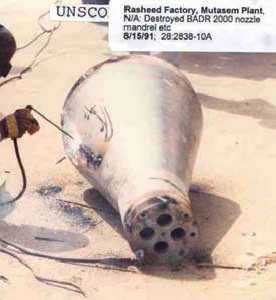

Nozzle mandrels

|

|

|

|

|

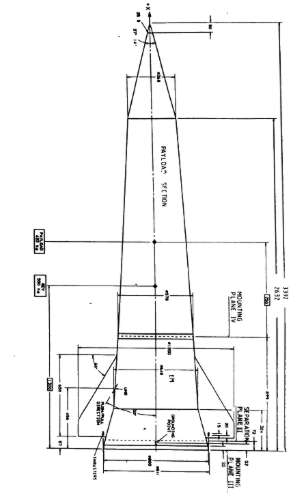

WH (Length 3.392 m)

|

Planned second stage propulsion

|

|

The

successor

BADR-2000 Junior |

|

|

|

|